Tools

Support

Pangolin Family of websites

Pangolin Laser Systems, Inc.

Kvant Lasers

Unity Lasers

ScannerMAX

Lasorb

Tools

Support

Pangolin Family of websites

Pangolin Laser Systems, Inc.

Kvant Lasers

Unity Lasers

ScannerMAX

Lasorb

Professional Audience Safety System

User Manual for PASS version 1.5 March 2015

PLEASE READ THIS ENTIRE MANUAL VERY CAREFULLY, INCLUDING THE LICENSE AGREEMENT AND LIMITED WARRANTY FOUND IN THE BACK OF THIS MANUAL. FAILURE TO FOLLOW THESE INSTRUCTIONS VERY CAREFULLY COULD LEAD TO AN INCREASED RISK OF AN UNSAFE LASER EXPOSURE.

This manual contains important information on how to install PASS in a laser projector, how to perform adjustments, and how to make sure that the show remains safe – including a requirement to test your laser projectors before each show and log the test results.

Congratulations on selecting Pangolin’s Professional Audience Safety System, an important step toward helping to keep your audiences safe from the potential hazards that laser projection systems may pose. You have purchased a powerful and patented laser projector safety monitoring system for laser light show usage.

This manual serves as a brief introduction to PASS, so you can install it and get started.

Pangolin provides you with the PASS hardware board, connection cables, and this manual.

You must provide a laser projector including laser, scanners, shutter and power supply.

You must also use a light sensor to ensure maximum protection. An optional control panel may also be used for maximum flexibility.

PASS is a sophisticated system which, when properly integrated into a laser projector and used with the proper show presentation techniques and Pangolin software, can assist in maintaining the safety of Audience Scanning laser shows.

PASS is barely bigger than a credit card, and yet it includes a set of very sophisticated and complete protection systems.

PASS hardware is designed with multiple levels of redundancy and with circuitry that is designed to fail-safe. In fact PASS is designed to maintain safety even in the face of several simultaneous failures.

Although the PASS hardware circuit board itself is designed with redundant circuitry, some of the redundancy of the entire system is provided by external elements, such as the shutter, light sensor, and projector interlock. This is why these additional items are very important, and mandatory for most uses of PASS.

This manual discusses how to install, connect, and adjust PASS. You must read and fully understand this manual before installing and using PASS. Pangolin also conducts private training sessions that integrators must attend, before Pangolin will sell the PASS hardware.

NOTICE! Pangolin will only guarantee the proper operation of PASS when it is used in conjunction with Pangolin software and control hardware (i.e. QM2000, FB3 or FB4). In addition, Pangolin strongly recommends the use of only ScannerMAX series of scanners and servo drivers, or alternatively Cambridge model 6210 or 6215 scanners with associated servo drivers made by Cambridge Technology.

Ideally the PASS circuit is installed inside the projector, rather than externally. PASS may be inserted into the ILDA (analog signal) signal stream, or alternatively inserted into the signal stream after your own projector electronics (such as differential color receivers or scanner invert switches) but before the scanner servo drivers and laser modulators or drivers. Given this location within the signal path, PASS is able to interrupt the flow of the color signals, as well as forcibly close the shutter and open the projector Interlock circuit if necessary.

PASS monitors the following projector-health-related properties:

When power is not applied to PASS, or when PASS detects that the power supply is not sufficient to properly operate the laser projector, PASS will crowbar (short-circuit) the color signal inputs, and forcibly close the shutter and intensity outputs. PASS will also open the projector interlock signal path (ILDA pins 4 and 17). As long as a fast shutter is located within the beam path and as long as the interlock signal path is used within the projector, this dual action will prevent light from being emitted from the projector under all circumstances.

Since the shutter is closed and projector interlock are opened during critical fault conditions, these two external elements are able to work in a redundant fashion, incase either of these were to fail individually. Because of this, PASS requires the use of both the shutter, and projector interlock.

PASS monitors the X and Y position signals and derives Euclidian vector velocity as well as effect size. If the vector velocity is found to be below the Minimum Velocity (the minimum speed that the beam is required to sweep, in X and/or Y, in order to be considered to be safe), and found to remain there for a period longer than the Dwell Time (the time that a beam may remain at or below the minimum velocity see page), PASS will blank (pull to zero volts) all color signals and the intensity signal. PASS will only do this for the period of time that the beam is below the “Minimum Velocity”. As soon as the beam speeds back up, or the beam enters a non-protected area (i.e. above the horizon if enabled), PASS will allow the color signals to flow from the Input to the Output. The Effect Size has a similar result, and this is included in PASS as a measure of redundancy. If there is an effect that is scanning very quickly, and which would satisfy the “Minimum Velocity”, but if this is a very small effect, PASS will blank the color and intensity signals until the Effect Size resumes a safe level. The Effect Size is not adjustable on this version of PASS. Note that during momentary interruptions of color and blanking signals, PASS does not affect the Shutter output.

A control panel may optionally be used with PASS. The control panel may have a ESTOP switch (i.e. mushroom emergency stop switch), as well as a manual reset button, which may be embodied as a keyswitch or push button. When a control panel is used with PASS, a Manual Reset is required in order to activate PASS, and thus, start projector operation. In most cases, this is a simple keyswitch action but could also be a simple momentary push button. And when a Control Panel is used, PASS continually monitors the ESTOP button. If the ESTOP is pressed, PASS will immediately terminate all color and intensity signals, and forcibly close the shutter. PASS will also open the projector interlock signal path (ILDA pins 4 and 17).

The Beam Power Monitor is perhaps the most unique and important aspect of PASS. The Beam Power Monitor is able to make sure that the light coming out of the projector conforms to what is expected. When PASS commands that no light should be emitted from the projector, PASS will verify that this is so, by observing the Beam Power Monitor. If light is coming out of the projector when it is not supposed to be, PASS will forcibly blank the color and intensity signals, close the shutter, and open the projector interlock signal path. PASS does this because this would be considered a critical problem. Likewise, if PASS detects that light is commanded from the computer, but is not coming out of the projector, PASS will take this same kind of critical action, because this could be a sign that the light sensor is not working. And finally, PASS will measure the Beam Power against a “Maximum Safe Beam Power” adjustment, and if it is exceeded, PASS will take the same critical action, forcibly blanking the color and intensity signals, closing the shutter, and opening the projector interlock. Any of these conditions requires the power to be recycled, or a Manual Reset. Under normal circumstances, this will never occur. There should always be congruence between commanded power and actual light coming from the projector. And light coming out of the projector above the “Maximum Safe Beam Power” level is, of course, also a sign of trouble. See the section on “Using PASS with a light sensor” below for additional information.

The PASS circuitry is implemented almost entirely in analog circuitry. There are logic circuits within PASS, but these logic circuits are entirely combinatorial in nature. This means that the logic is made up of simple AND and OR statements, which can be easily understood by peers in the safety community. There are no sequential-logic circuits within PASS, nor are there any microprocessors, which could not be fully validated.

In addition to the logic used by PASS to implement the basic safety features, PASS also includes a separate layer or logic that actually watches the first logic layer, and verifies sanity. If there is a problem within the PASS logic, the color and intensity signals are blanked, the shutter is closed, and the projector interlock signal path is opened. The system will remain in that state until power is recycled, or until a Manual Reset is performed.

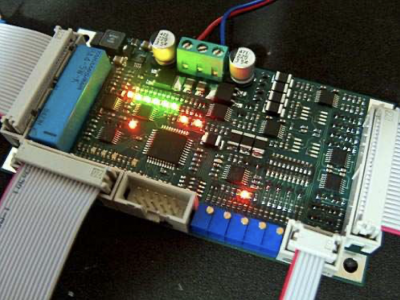

The general layout of PASS is shown above, with connectors identified.

Pangolin includes connectorized ribbon cables with PASS. These ribbon cables can be used directly, allowing minimal effort to integrate PASS within a projector. When ribbon cables have a red stripe on one side, the red stripe indicates the side of the cable associated with pin 1.

The Projector-Signal-Input to PASS may come directly from the DB- 25 input on the projector, or may come after projector internal electronics that condition the color signals (for example, allow adjustment of intensity for each color or scanner axis inversion and rotation). When PASS is used for direct projector input, a simple crimp-on DB-25 connector may be used, and crimped onto the Projector-Signal-Input ribbon cable provided with PASS.

The Projector-Signal-Output connector on the PASS board should be parsed out into pairs of signals, and then directed to various components within the projector. The signals and recommended connections are discussed below. Note that since this is an IDC connector, the pin numbers do not correspond to the ILDA pin-out on a DB-25. HOWEVER, if you crimp a DB-25-connector onto the output ribbon cable, then the pins will correspond directly to the ILDA pin-out. This is because the pin designations of a DB-connector are “in-line” while the pin designations of an IDC connector are “even and odd”.

Note: There should NOT be a connection to the “signal ground” of any scanner amplifier. The only “ground” connection to the scanner amplifier (or amplifiers) should be from the power supply itself. Connecting to the “signal ground” on a scanner amplifier will introduce a ground loop, which may cause distorted images. See the “Power and X-Y Position Signal Connections” on the following pages.

Note that for the color signals above, ideally, any Laser Diode Driver should have differential input, and you should connect both the + and – color signals from the PASS board directly to those drivers.

PASS may be controlled by, and may illuminate LEDs on an external control panel that is connected to PASS. Below is a description of the control panel connections. When PASS is not connected to an external control panel, then PASS will automatically reset into a “ready” state shortly after power up. When PASS is connected to an external control panel, then PASS will not power up in a “ready” state and instead, will wait for the “Manual Reset” from the control panel.

Note that some jurisdictions including the U.S.A. require a manual reset in order to activate the projector after power up. The PASS control panel connector may be used to help facilitate this feature.

Also note that the signals presented to this connector are generally connected directly to PASS logic circuits. The signals are not protected from ESD or other electrical faults. For that reason, it is recommended that any external signals that are connected to this connector be short (i.e. don’t connect a 30 meter long cable from the external box to the PASS board…)

Note that unlike the other LED outputs on the control panel connector, the “Status LED” outputs will “latch” in the event that a fault is detected. They will remain in the latched state until a Manual Reset occurs. This allows you to determine the cause of any detected faults.

The “Status LED” signals may be routed through a resistor to an LED on the control panel to give an indication of any faults that have been detected.

PASS monitors the power supplies that feed the scanner amplifiers. This voltage can be between +/-20 volts and +/- 30 volts. The manor in which you connect PASS to the power supply and to the scanner amplifiers depends heavily upon whether you are using two separate single-axis scanner amplifiers, or one dual-axis scanner amplifier.

If you are using two separate single-axis scanner amplifiers, the recommended connections are shown below:

Note that each scanner amplifier, as well as the PASS circuit board itself must each have their own power wires going back to the power supply. These wires should all meet at the power supply itself. If you have two power supplies (one for +24V and the other for –24V) then these power supplies should establish a central connection where all wires meet. This is called a “single-point grounding scheme. Wiring the power supply in any other way will cause a ground loop, which may cause distorted images during projection.

Also note that when using two separate single-axis scanner amplifiers, you run only the POSITION signal to the PASS position input. DO NOT connect any additional ground wire from each scanner amplifier to the PASS board. Doing so would introduce a ground loop, which may cause distorted images.

If you are using a one dual-axis scanner amplifier, the recommended connections are shown below:

Since there is only one scanner amplifier in this case, the scanner amplifier is connected directly to the power supply. If you have two separate power supplies (one for +24V and one for –24V), these can be connected at the scanner amplifier itself. The PASS board is also connected at the scanner amplifier itself.

Note that in this case, it is permitted to connect a separate “position signal ground” from the scanner amplifier to the PASS board if you wish.

PASS includes a number of switches that must be configured to customize operation to a particular projector or projection scenario. Below you will see the PASS board and location of the switches. The operation of each switch is described below.

As was the case with the switches, PASS includes five potentiometers that must be adjusted to customize the operation of PASS to a particular projector or projection scenario. Below you will see the PASS board and location of the five adjustment potentiometers. The operation of each potentiometer is described below.

You can adjust the “Maximum Safe Beam Power” and “Minimum Power” adjustments by looking at D208 “Light Sensor State” bi-color LED on the PASS board.

Also note that the “Maximum Safe Beam Power” and “Minimum Power” adjustments are ignored if the switch 4 is turned “on” (see switches on page 20).

NOTE: The information contained in this section must be understood and followed very carefully in order to ensure that PASS operates correctly, and to minimize the risk of an unsafe laser exposure.

Since the procedure described below involves projecting patterns into an area that an audience will eventually occupy, and since the light levels experienced during adjustment procedure may exceed the MPE under some circumstances, it is highly recommended that you perform the procedure below when the venue is only occupied by trained technical staff, and communicate very clearly when the laser will be turned on so that staff will know how to react. To avoid the possibility of illuminating people who may not understand the technology or potential risks that a laser projector may present, the adjustments and procedures described below should preferably be done in a laboratory environment, not in the venue where personnel (for example waitresses, etc.) may be walking around before the venue opens.

During this first test, it is important to use the lowest amount of laser power possible. This will reduce the chance of illuminating personnel that might be in the room during these tests. For the next few tests and adjustments, the beam power is best reduced by using the software brightness level setting – rather than potentiometers that might reside on the back of a laser projector.

First, set PASS Switch 3 to “Protect only the bottom portion” (switch moved to the left, if the board is physically oriented as shown on Page 20). Also, set Switch 4 to “Light sensor not used” (switch moved to the left.) These switch positions are necessary for the next few adjustments.

Next, output a slow-moving circle (for example, somewhere in the 1Hz to 5Hz range) using a function generator or abstract generator feature of the software. The circle should be somewhere between 50% and 100% size for this test. Note that while doing this and if PASS is not set correctly, the laser beam will probably be allowed to enter the audience area. Therefore it is once again important to make sure there are no untrained or non-technical personnel present in the room during this setup.

At this point and with this kind of pattern being projected, you should see that – while the beam is above the audience area, it is visible, and while the beam is within the audience area, it is extinguished. If you do not see this, then it is possible that the Horizon potentiometer is set so far in one direction, that PASS thinks the entire scan field is above the horizon. In such a case, turn the Horizon potentiometer several turns clockwise, and then several turns counterclockwise, until you see that there is an area where the beam is blanked. If you never reach a point where the beam is not extinguished, then stop right there and make sure PASS is wired correctly – particularly with respect to the scanner position signals.

Next, adjust the Horizon potentiometer clockwise, and counter- clockwise, to position the area (horizon) such that the beam is extinguished when it is in the audience area.

Once this is done with the slow-moving circle, COLLAPSE the Y axis (change Y size to zero in the software), which will project essentially a slow-moving horizontal beam – centered on the Y-axis. You will want to make sure that the beam is extinguished in this configuration, because it is important when the projector has no scanning input (i.e. X and Y projector inputs at zero) that no light will come out of the projector.

Now adjust the Y position control in the software upward, to the point where the beam becomes visible again. You want this to be at least 2% upward. If the beam becomes visible at 1% upward position on Y, adjust the Horizon control again to extinguish the beam.

Once the Horizon is verified above, return the Y position control in the software to 0.

Now that the PASS horizon has been adjusted, it can be used to aid in preparing to evaluate the maximum laser power that will be allowed in the audience.

At this point it will be necessary to configure the software to output a stationary, non-modulated laser beam. In LD2000 this can be done by going to the Abstract Generator (menu SFX/Abstract Generator), and then reducing the size of the default abstract to zero, and then pressing OK.

If you have adjusted the horizon properly, you should see NOTHING coming out of the laser projector. Otherwise, go back and repeat the steps above, ensuring that the Horizon potentiometer is adjusted properly.

Since the point is to determine the maximum amount of laser power that will be safe in the audience, this should be done with any projector-based power-level adjustments defeated. For example, if the projector has potentiometers (or digital adjustments) accessible from the rear, that can be used to reduce the beam power, these adjustments should be set all the way at maximum, so that the power level coming out of the laser projector is entirely controlled by the software input.

Now – in the Projector Settings dialog box, make sure that the brightness level is turned down – perhaps to 10%.

Slowly move the Y Position control upward, until the beam hopefully becomes visible. If the beam does not become visible after a substantial upward movement of Y Position, then adjust the brightness level upward until a beam is seen.

Now, using a laser power meter that has a 1 square centimeter (or approximately 11mm round) detector, place the detector of the power meter into the stationary beam – AT THE CLOSEST POINT OF AUDIENCE ACCESS. It might be handy to mount the detector head of the power meter onto a tripod stand, so that it can be held into the stationary beam.

The laser beam should be larger than the 1 square centimeter power meter detector area. If it is not, then you will need to increase the divergence of the laser beam, for example, using one of Pangolin’s SafetyScan lenses. (A beam smaller than 11mm round in the audience will certainly not be safe, unless the power is around 10 milliwats…)

When the laser beam is larger than the 1 square centimeter active area on the power meter, then the power meter will read in terms of Watts Per Square Centimeter (also known as “irradiance”), instead of Watts (also known as “radiant power”). This is an important concept that must be understood. The laser safety standards are based on irradiance, not radiant power!

Using the software brightness control, increase the beam power upward and upward and upward until the laser power meter reads the desired level of irradiance – according to the MPE that you are trying to accomplish. Although PASS allows for a large degree of adjustment, laser industry best practices generally assume that the irradiance will be no greater than 10 milliwatts per square centimeter for a 1 millisecond pulse width described below.

Now that you have determined the maximum brightness level that the software can output to accomplish the desired irradiance, you should write this down on a piece of paper, or otherwise record it. For example, this might be a brightness level of 27%. This means that you will need to paint a brightness level of 27% into the Beam Attenuation Map, or use other software features to ensure that the beam power never exceeds the maximum safe power level determined in this step.

Adjust the Maximum Beam Power potentiometer on PASS, many turns clockwise. The idea is to set this to a level that won’t immediately trip once you enable it using Switch 4.

Now, go to the Abstract Generator and increase the size to project a circle. Any other pattern may be projected, but it’s best to keep the pattern simple.

If you have done everything correctly and followed the instructions carefully, at this point you should see a circle or pattern projected at what is essentially the maximum power that it will ever be in the audience.

Next, using the brightness level setting in the software, increase it a one percent past the level determined above. For example, if the maximum safe power was determined to be 27% brightness, you should increase the brightness level setting to around 28%. This should output a power level a bit higher than the maximum determined in the step above.

Next, enable the light sensor by moving PASS Switch 4 to the “Light sensor is used” setting (switch moved to the right).

Next, slowly turn the Maximum Safe Power potentiometer counterclockwise, until PASS “trips”. Basically what you are doing in this adjustment is bringing the threshold down to the point where PASS will trip if it detects more beam power than was determined to be safe above.

Once PASS has “tripped”, it will need to be reset, either using the Manual Reset pins on the control panel connector, or by cycling power to the projector.

Before resetting PASS using control panel pins (or cycling power to the projector), reduce the brightness level setting in the software back to the level determined above (for example, 27%).

Once the projector is running again, you can verify the “trip” level, by adjusting the brightness level upward until it trips. We also recommend that you run a number of test patterns and show program material with the brightness set to the maximum safe power determined above (i.e. 27%). If the projector occasionally trips, then you might want to examine any filter or combiners used to “flatten” the spectral response curve of the light detector used in your projector. If PASS trips repeatedly, you may need to reduce the brightness level determined above (for example to 26% or so)…

If it is your intention for PASS to protect the entire scan field, then now would be the time to move Switch 3 “Protect entire scanfield” position (to the right). Otherwise you can simply leave the switch where it is.

Preparing to perform further measurements and adjustments

At this point you will be adjusting the velocity detector and dwell timers inside PASS. To do this, connect a fast photodiode to an oscilloscope. The photodiode should be the amplified type, so that the oscilloscope will show voltage as a result of light entering the detector. The Thor Labs model PDA100A is a good choice for an amplified photodiode.

A 7mm aperture must be placed in front of the photodiode entrance aperture. This might be done by cutting a 7mm hole in a piece of “Black Wrap” foil, and then placing this over the entrance aperture. The 7mm pupil allows the photodiode to measure the pulse width as a scanning beam crosses a 7mm dilated pupil.

The photodiode should be placed on a tripod, so that it can be moved into the beam path to perform safety-related measurements.

Once the photodiode is prepared as described above, use a function generator or software’s built-in ability to project a circle. The circle should preferably be continuous, and non-modulated. In LD2000 this is easily accomplished using the Abstract Generator. (Just go to SFX/Abstract Generator, and click OK.) The size of the circle should be such that it scans within the area where the audience will reside.

As with some of the tests above, during these tests, it is important to use the lowest amount of laser power possible. This will avoid overloading the photodiode and also reduce the chance of illuminating personnel who might be in the room during these tests.

Move the tripod and photodetector such that the circle scans across the 7m aperture – AT THE CLOSEST POINT OF AUDIENCE ACCESS – and look at the output on the oscilloscope. Preferably, the photodiode is positioned roughly in the center of the beam path as it scans past the detector. This should also be the brightest part of the beam. You should be careful, and be aware that photodiodes have shiny surfaces which can create mirror-like back-reflections. Therefore you must be very careful while placing the photodiode into the beam path, that the reflected stray beam will not accidentally wind up targeting personnel or an undesired location.

Adjust the voltage input and time setting on the oscilloscope so that you can measure the height (i.e. maximum voltage) of the pulses. During this part of the test, it is very important to make sure that the photodiode is not overloaded with light, and merely delivering a “saturated” maximum voltage to the oscilloscope, as this will artificially lengthen the pulse width. The PDA100A photodiode has an attenuator dial on the side to adjust the gain. Make sure that this gain setting is adjusted properly, so that the photodiode is not overloaded.

Once you have a reliable voltage measurement, the pulse width is determined at the “full width at half maximum” points on the waveform. For example, if the voltage waveform slopes from 0 volts upward to 4 volts, and then downward to 0 volts, essentially this means that the pulse width is the amount of time that the pulse is greater than 2 volts.

Since laser industry best practices are that audience scanning shows are done using the assumption of a 1-millisecond maximum pulse width, you should compare this against the pulse width seen on the oscilloscope. If the pulse width is shorter than 1 millisecond, then you will need to slow down the function generator (or Pangolin software abstract generator) until you get to a pulse width of 1 millisecond.

Generally, PASS should be adjusted to extinguish the laser beam for pulse widths greater than 1 millisecond. If you are able to slow down the function generator to obtain longer pulses, then this means that the MINIMUM VELOCITY adjustment on PASS must be increased (turned clockwise).

Now that the Minimum Velocity adjustment has been setup, you can move to the next part of the test, which ensures that the Maximum Dwell Time is adjusted properly. To do this, change the test pattern from a circle to a Quadrature Squarewave. (A Quadrature Squarewave is a pattern where the beam stops in four places, and jumps very quickly from place to place. The Abstract Generator in LD2000 has a drop-down list box where you can select the waveform that will be used.)

Move the photodiode and tripod into one of the corners of the quadrature squarewave, taking all of the precautions mentioned above. Adjust the voltage level on the oscilloscope, and adjust the attenuator dial on the photodiode to ensure that you have a reliable voltage measurement.

As described above, determine the pulse width at the “full width half maximum” points on the waveform. If the pulse width exceeds 1 millisecond, adjust the MAXIMUM DWELL TIME potentiometer counterclockwise.

When PASS is used with the “LIGHT SENSOR USED” switch setting, then a light sensor must be connected to J803 Pin 1, Pin2, and Pin 3.

When a light sensor is not used, J803 Pin 2 should be connected to Pin 1. Note: it should be understood that using PASS without a light sensor should only be allowed if you are using the PASS hardware as a simple scan-fail safeguard AND if the laser power is low enough to justify this AND if you implement additional safety-related systems down-stream from the PASS hardware. Contact Pangolin for more information if you are interested in using PASS without a light sensor.

When used, a light sensor must be installed within the beam path of the projector. Generally we recommend that the light sensor be placed before the final shutter, but it may also be placed after, as long as the final shutter opens faster than around 1/20th of a second.

Generally the light sensor is fashioned as a glass window that is used to “sample” the outgoing laser beam at a 45-degree (or so) angle, and direct a small portion of the laser beam to light-sensitive material.

The light sensor used with PASS must be a relatively fast sensor – one that is able to react as quickly as the light can be modulated. Generally this means that the light-sensor must be based on silicon photodiode or silicon PIN photodiode type technology.

If the projector is a multi-wavelength projector (e.g. an RGB projector), and a single light sensor is used in the combined beam path, then the light sensor must have an additional “spectral flattening” filter to make the light sensor provide the same output for all wavelengths. This is because the safety standards treat all visible wavelengths the same. Since silicon detectors have a peak response in the near infrared and since their response tends to trail off toward the visible blue spectrum, this filter appears to the naked eye as a bluish piece of glass – allowing light in the blue end of the spectrum to pass freely, while attenuating longer wavelengths more progressively. These tend to be specialized filters, generally matched to a particular photodiode, and therefore we have not found a place that sells just the filter by itself.

An alternative to using a single sensor in the combined beam path would be to put individual light sensors after each separate- wavelength laser, and sum the output of all of the light sensors so that the total output voltage sent to PASS corresponds linearly with wattage (i.e. delivers the same amount of voltage for the same amount of power from each separate wavelength).

The output of silicon photodiodes cannot be directly connected to PASS. Instead the photodiode output must be amplified, and turned into a zero-to-5-volt analog signal, where zero volts represents no light being detected and 5 volts represents the maximum voltage delivered to PASS. Note that PASS provides a connector with 5 volts, so this is where the light sensor and amplifier can get its power.

Since PASS has adjustments for MINIMUM POWER and MAXIMUM SAFE POWER (see page 22), the output of the sensor does not need to reach all the way to 5 volts when maximum light is coming out of the projector. Likewise, the sensor may deliver 5 volts even before the maximum light power level is reached. Any maximum-light-output scale factor can be used as long as around 4 volts or less represents the maximum safe light level for audience scanning (which would generally be lower than 1 watt, but could be more depending on the distance of the projector to the audience and other factors).

Under the most ideal circumstance, the photodiode should be amplified with a logarithmic amplifier (also called “log-amp”), because when this is done, the voltage output from the amplifier will correspond to light power (i.e. watts), not just light intensity. However, a simple op-amp amplifier may be used, as long as it has enough dynamic range that a few milliwatts of power delivers a detectable voltage level (and can satisfy the “MINIMUM POWER” adjustment) and also maximum safe light level is reached before around 4 volts.

Presently, the only ready-made product that is readily available on the market, which has a silicon detector with the “spectral flattening” filter attached and logarithmic amplifier board is the model SEL033 detector with model F “flat response” filer, and model A430 amplifier, all available from International Light Technologies corporation. Note that these components are generally not stocked items, and normally they have to be pre-ordered from the company. Also note that these are large and bulky, so they may not be appropriate for compact projectors. And finally the combination of these parts does not constitute a complete light sensor ready to be used in a laser projector. The sampling window and mounting hardware are additional items that need to be fashioned within the projector to create a whole light sensor package.

Using a light sensor with PASS can be tricky. When you enable the light sensor feature in PASS, everything must be at least ready to operate correctly. Otherwise PASS will detect problems and “trip” – forcibly shutting the projector down, requiring either a manual reset (i.e. by briefly shorting pin 3 to pin 4 on the Control Panel Connector) or the power being re-cycled.

PASS will forcibly shut the projector down under the following critical circumstances:

Using the light sensor with PASS affords the maximum level of protection, because if the laser power is increased above the MAXIMUM SAFE POWER within the designated audience area (i.e. the entire scan field, or only below the horizon depending on a switch setting) PASS will immediately shut down the laser projector. Therefore Pangolin considers it to be mandatory that a light sensor be used in safety-critical situations.

Because setting up PASS with a light sensor can be tricky and may be frustrating to get it working perfectly, we recommend clients work closely and directly with Pangolin during this phase of projector integration.

The mere act of putting PASS inside a laser projector will not instantly and automatically allow it to be used within the United States for audience scanning. For that to occur, both the projector and the show will need a variance, in exactly the same way that both the projector and show would need a variance if it were not used for audience scanning. However, obtaining a variance for an audience- scanning projector and even an audience-scanning show takes quite a bit of time and skill on the part of the variance applicant.

In recent years, PASS has become a well-known name brand product, and the decades-long-employees (founding fathers if you will) of the US Center for Devices and Radiological Health know PASS by name. Nevertheless, simply mentioning PASS by name, in your variance application, should not be expected to quickly open any doors… An audience-scanning variance application must describe what PASS does, along with the other projector features (for example, no doubt including a lens installed either inside or outside the laser projector to increase divergence) to help ensure audience safety. Finally, the audience-scanning variance must include documentation on how the projector is setup, how measurements are performed and verified, and how the projector is used at each event in ways that ensure audience safety. For the most part, an audience-scanning variance application covers the same things that a more ordinary variance application covers, but it covers them in a more rigorous way.

While drafting variances for audience scanning, and for general knowledge of what PASS does and how it works, some people have found it handy to refer to the Patents on PASS. The issued US patent can be found on the USPTO web site, or on Google Patents. It is called “Laser projector safety monitoring system” and is covered by US Patent number: 7,756,174. In Europe, the patent application can be found at the World Intellectual Property Organization web site. It is called “Laser projector for audience scanning” and is covered by number: EP20060733773. In Australia, the issued patent can be on the IP Australia web site. It is called “Laser projector for audience scanning” and is covered by Australia Patent number 2006206400.

For those who do not have a lot of skill with filling out US Government paperwork, we recommend a laser safety consultant, such as Greg Makhov, Casey Stack or Jay Parkinson. Within Europe and the United Kingdom, we recommend James Stewart.

Although PASS monitors the real-time activity of the laser projector power supply, scanner velocity, optional laser output power and optional control panel signals, PASS, by itself, cannot ensure the safety of a laser show. Divergence-modifying elements (such as the SafetyScan lens) are actually more critical to audience safety than is PASS. This is because under normal circumstances, (i.e. when everything is working properly and you are using proper divergence and show presentation techniques) PASS plays only a secondary and passive role in audience scanning safety, whereas a divergence increasing lens and proper show performance techniques play a primary and continuous role in audience scanning safety.

And although the PASS hardware has been designed to be self-testing and employs redundant circuitry, it is ultimately an electronic circuit, and it is conceivable that, under certain rare circumstances, the PASS circuitry could fail in such a way that it would not prevent an unsafe laser exposure. This is why the Professional Audience Safety System is not considered to be only the PASS hardware circuit board by itself, but rather an entire safety system, which includes the external light sensor, external shutter, and projector interlock. It is only when all of these things are used together and properly adjusted, that there will be sufficient redundancy and monitoring to reduce the risk of an unsafe laser exposure.

Of course the adjustments on PASS must be configured properly, for the scanning velocity and dwell time as well as the projection horizon (if used). Moreover, the light-sensor-related adjustments on PASS must be configured to monitor the minimum beam power of the laser (to ensure proper light sensor and laser diode driver operation) as well as the maximum beam power of the laser (to ensure that exceeding a safe power level will be detected by PASS).

And finally, it is clear that in order to ensure continued and repeated safe performance, tests of the entire projection system must be conducted before each show performance (for example nightly), to make sure all elements of the projector and computer system feeding the projector as well as the PASS hardware itself are all working as expected. At a minimum, these tests should involve the projection of test patterns specifically designed to demonstrate that PASS and other safety features are working properly (both inside the audience area and outside), and that PASS will properly extinguish the laser beam when needed, as well as properly disabling the projector (i.e.“tripping”) if the Maximum Beam Power is exceeded. (Please contact Pangolin if you need assistance in the creation of such test patterns.)

The performance of these tests, along with any measurable analytical results should be logged, and the log should be permanently kept in a safe place, so that it can be reviewed later if needed.

If any of the tests mentioned above provoke unexpected results, the projection system should not be used for the laser show performance until the entire projection system has been examined and any problem discovered has been remedied.

THIS IS A LEGAL AGREEMENT (the “Agreement”) between you and Pangolin Laser Systems, Inc. (“Pangolin”) as manufacturer and licensor of the Professional Audience Safety System (PASS). This Agreement provides you with the authorization to use PASS subject to the terms and conditions herein. If you do not agree to all the terms and conditions of this Agreement, do not use PASS. If you proceed to use PASS, you thereby signify that you have agreed to all of the terms and conditions set forth below.

© Pangolin Laser Systems, Inc. All rights reserved.

Due to our policy of continuous product improvement, information in this manual is subject to change without notice.

NOTICE: The electronic circuit design of PASS as well as concepts embodied within it, are protected by U.S. and Australia patents. Due to our policy of continued product development in the area of laser safety, other patents may also be pending.