Tools

Support

Pangolin Family of websites

Pangolin Laser Systems, Inc.

Kvant Lasers

Unity Lasers

ScannerMAX

Lasorb

Tools

Support

Pangolin Family of websites

Pangolin Laser Systems, Inc.

Kvant Lasers

Unity Lasers

ScannerMAX

Lasorb

Audience scanning is one of the most beautiful things you can do with a laser. Indeed, it's what separates lasers from any other lighting effect or medium, because with Audience Scanning, the light literally reaches out and touches the audience. However, there are a few potential hazards to overcome. When audience scanning shows are performed the typical way (using the raw laser beam) that beam is typically so small that the entire beam's power can enter a show-viewer's eye. Where safety regulations are strictly enforced, such as the US, UK and Australia, studies have shown that the maximum amount of un-diverged laser power you can use while complying with the MPE is only around 10 milliwatts. Obviously, such a low laser power would not make a very effective show. Outside of these countries, and where safety regulations are more relaxed or not enforced as vigorously, often times higher laser power is used. Nevertheless, aside from safety concerns, when high power lasers are used, audience scanning effects can be unpleasant as they sweep past a viewer’s eye. This is because, again, the beam is so small that the entire beam's power scans across the pupil of the eye.

One easy solution is to use Pangolin's SafetyScan lenses. They increase the divergence of the laser, but only within the audience area. Once affected by Pangolin’s SafetyScan lenses, the beam becomes bigger, and because the beam is bigger, this effectively lowers the irradiance (beam power per unit area) that enters the pupils of the audience members. Due to the inverse-square law that governs light, this means that higher actual laser power can be used, because the size of a laser beam is increased in both the horizontal and vertical dimensions. The result is that higher laser power can be used, and the show is much more effective. The side benefit is that since the beam is bigger, it also makes a much more pleasant, softer audience scanning experience, but only in the audience area. When the SafetyScan lens is used correctly, the laser beam is unchanged above the heads of the audience, so the “marbling” effect seen in fog remains, and the spectacle, brilliance and drama of an audience scanning laser show are retained. Mirror targeting can also be performed above the heads of the audience.

A SafetyScan lens can easily be mounted directly to the front of any laser projector, either using a mount from Pangolin or using a self-made mounting arrangement. And due to the simple “binary” nature of the SafetyScan lens (the laser beam is either affected or it isn’t), the SafetyScan lens is a simple and reliable solution.

Once the proper SafetyScan lens is installed on a projector in a reliable manor, the result is a show that can be more powerful, and also much safer and much more pleasant to view.

In addition to the information provided below, Pangolin has also produced a 15-minute video showing how to mount the lens, how to perform safety measurements, and the resulting laser shows.

(how the lens affects the beam divergence and spot size)

The effective projected divergence, and thus, the spot size in the audience caused by the SafetyScan lens, depends on the incoming beam divergence (i.e. divergence before the lens), and the beam quality parameter (M2) of the incoming laser beam. It is important to understand that the better the beam quality (lower values of M2), the less of the effect that the SafetyScan lens will have on the laser beam divergence. For a detailed explanation of M2, see the Wikipedia article here: http://en.wikipedia.org/wiki/M_squared

Below you will find tables that show the spot size at distances ranging from 5 meters to 35 meters from the projector, for laser beams whose full-angle divergence is 1.0 mRad, 2.0 mRad and 3.0 mRad, having beam quality parameter (M²) of 1.2, 3.0 and 5.0. The “Divergence” column on the right shows the approximate effective divergence with a lens in place.

Note that the beam divergence and M² of the laser beam work together in nonlinear ways, and thus the values in the tables may seem unintuitive. Also note that the tables were calculated for a green wavelength, and that the lens has a greater effect for red wavelengths and lesser effect for blue wavelengths.

It is important to understand that the tables below represent theoretical values based on Gaussian beam physics. Since real-world lasers usually have less than ideal beam characteristics, it means that the tables should serve as a starting point for lens selection, and not as a definitive final answer. Many laser manufacturers do not state their beam quality parameter (M²) and thus, this may not be easy to obtain. Moreover, for poor- quality lasers, the M² may change over time, or the beam may be distorted by other projector optics.

It is recommended that you observe the spot size on the exit aperture window of the laser projector and compare this with the “Spot size at the exit aperture” stated below within the tables. Then look at the spot size at your target distance and compare this with the spot size shown in the table for no lens. These two will help to give you a “sanity check” of your divergence and probable M2 of your laser. Then choose a lens that provides the desired spot size.

Note that Pangolin strongly suggests that, once the lens selection is made and the lens is in place, you measure the laser beam irradiance using an energy meter, to confirm that it is safe for audience scanning. As implied by the License Agreement and Limited Warranty below, PANGOLIN WILL NOT BE HELD LIABLE FOR MIS-APPLICATION OF THE SAFETY-SCAN LENS OR LENS MOUNT.

When the beam quality (M²) is close to 1.0, it represents a near perfect, Gaussian beam. Lasers with this kind of beam quality may include lasers that use gases including Argon, Krypton, Helium-Neon, etc. Coherent Optically-Pumped Semiconductor Lasers also have very good beam quality with low M². Some low power, high quality DPSS lasers may also have M² of around 1.2.

Laser beam with 1.0 milliradian full-angle divergence and M² of 3

(Spot size at the exit aperture of the projector = 1.99 mm)

| Distance in Meters | 5 | 10 | 15 | 20 | 25 | 30 | 35 | Divergence |

|---|---|---|---|---|---|---|---|---|

| No lens | 5.61 | 10.44 | 15.38 | 20.35 | 25.33 | 30.32 | 35.31 | 1.00 |

| 1 diopter | 13.51 | 25.19 | 36.87 | 48.55 | 60.24 | 71.92 | 83.60 | 2.40 |

| 2 diopter | 23.06 | 44.18 | 65.31 | 86.43 | 107.55 | 128.67 | 149.80 | 4.30 |

| 3 diopter | 32.85 | 63.74 | 94.62 | 125.51 | 156.39 | 187.28 | 218.16 | 6.30 |

| 4 diopter | 42.72 | 83.46 | 124.19 | 164.93 | 205.67 | 246.41 | 287.15 | 8.20 |

| 5 diopter | 52.61 | 103.25 | 153.88 | 204.51 | 255.14 | 305.77 | 356.41 | 10.20 |

| 6 diopter | 62.53 | 123.07 | 183.62 | 244.16 | 304.70 | 365.25 | 425.79 | 12.20 |

Laser beam with 2.0 milliradian full-angle divergence and M² of 1.2

(Spot size at the exit aperture of the projector = 0.64 mm)

| Distance in Meters | 5 | 10 | 15 | 20 | 25 | 30 | 35 | Divergence |

|---|---|---|---|---|---|---|---|---|

| No lens | 10.51 | 20.51 | 30.50 | 40.50 | 50.51 | 60.51 | 70.51 | 2.0 |

| 1 diopter | 13.22 | 25.87 | 38.52 | 51.18 | 63.84 | 76.49 | 89.15 | 2.6 |

| 2 diopter | 16.10 | 31.61 | 47.12 | 62.63 | 78.15 | 93.66 | 109.17 | 3.1 |

| 3 diopter | 19.08 | 37.55 | 56.03 | 74.51 | 92.98 | 111.46 | 129.94 | 3.7 |

| 4 diopter | 22.12 | 43.62 | 65.12 | 86.63 | 108.13 | 129.64 | 151.14 | 4.3 |

| 5 diopter | 25.19 | 49.76 | 74.33 | 98.91 | 123.48 | 148.05 | 172.62 | 4.9 |

| 6 diopter | 28.29 | 55.96 | 83.62 | 111.29 | 138.96 | 166.62 | 194.29 | 5.6 |

Laser beam with 3.0 milliradian full-angle divergence and M² of 1.2

(Spot size at the exit aperture of the projector = 0.79 mm)

| Distance in Meters | 5 | 10 | 15 | 20 | 25 | 30 | 35 | Divergence |

|---|---|---|---|---|---|---|---|---|

| No lens | 15.75 | 30.75 | 45.75 | 60.75 | 75.76 | 90.76 | 105.76 | 3.0 |

| 1 diopter | 19.57 | 38.36 | 57.16 | 75.96 | 94.75 | 113.55 | 132.35 | 3.8 |

| 2 diopter | 23.43 | 46.09 | 68.74 | 91.40 | 114.05 | 136.71 | 159.36 | 4.6 |

| 3 diopter | 27.33 | 53.88 | 80.42 | 106.97 | 133.52 | 160.06 | 186.61 | 5.3 |

| 4 diopter | 31.25 | 61.71 | 92.17 | 122.63 | 153.09 | 183.55 | 214.01 | 6.1 |

| 5 diopter | 35.17 | 69.56 | 103.95 | 138.34 | 172.73 | 207.11 | 241.50 | 6.8 |

| 6 diopter | 39.11 | 77.44 | 115.76 | 154.09 | 192.41 | 230.74 | 269.06 | 7.7 |

Lasers with M² around 3.0 may include direct diode lasers. Note that diode lasers usually have divergences that differ between the horizontal and vertical axis, and thus the SafetyScan lens may have a drastically different effect in the shape of the laser once in place. As with the rest of the information in this manual, these tables should be used as a starting point and not as the definitive final answer.

Laser beam with 1.0 milliradian full-angle divergence and M2 of 3

(Spot size at the exit aperture of the projector = 1.99 mm)

| Distance in Meters | 5 | 10 | 15 | 20 | 25 | 30 | 35 | Divergence |

|---|---|---|---|---|---|---|---|---|

| No lens | 5.61 | 10.44 | 15.38 | 20.35 | 25.33 | 30.32 | 35.31 | 1.00 |

| 1 diopter | 13.51 | 25.19 | 36.87 | 48.55 | 60.24 | 71.92 | 83.60 | 2.40 |

| 2 diopter | 23.06 | 44.18 | 65.31 | 86.43 | 107.55 | 128.67 | 149.80 | 4.30 |

| 3 diopter | 32.85 | 63.74 | 94.62 | 125.51 | 156.39 | 187.28 | 218.16 | 6.30 |

| 4 diopter | 42.72 | 83.46 | 124.19 | 164.93 | 205.67 | 246.41 | 287.15 | 8.20 |

| 5 diopter | 52.61 | 103.25 | 153.88 | 204.51 | 255.14 | 305.77 | 356.41 | 10.20 |

| 6 diopter | 62.53 | 123.07 | 183.62 | 244.16 | 304.70 | 365.25 | 425.79 | 12.20 |

Laser beam with 2.0 milliradian full-angle divergence and M² of 3

(Spot size at the exit aperture of the projector = 1.11 mm)

| Distance in Meters | 5 | 10 | 15 | 20 | 25 | 30 | 35 | Divergence |

|---|---|---|---|---|---|---|---|---|

| No lens | 10.55 | 20.53 | 30.52 | 40.52 | 50.51 | 60.51 | 70.51 | 2.0 |

| 1 diopter | 14.29 | 27.72 | 41.16 | 54.59 | 68.03 | 81.47 | 94.91 | 2.7 |

| 2 diopter | 18.93 | 36.88 | 54.84 | 72.80 | 90.76 | 108.71 | 126.67 | 3.6 |

| 3 diopter | 23.95 | 46.87 | 69.80 | 92.73 | 115.65 | 138.58 | 161.51 | 4.6 |

| 4 diopter | 29.16 | 57.26 | 85.37 | 113.48 | 141.58 | 169.69 | 197.8 | 5.7 |

| 5 diopter | 34.47 | 67.87 | 101.27 | 134.67 | 168.07 | 201.47 | 234.87 | 6.7 |

| 6 diopter | 39.84 | 78.60 | 117.36 | 156.12 | 194.88 | 233.64 | 272.40 | 7.8 |

Laser beam with 3.0 milliradian full-angle divergence and M² of 3

(Spot size at the exit aperture of the projector = 1.00 mm)

| Distance in Meters | 5 | 10 | 15 | 20 | 25 | 30 | 35 | Divergence |

|---|---|---|---|---|---|---|---|---|

| No lens | 15.76 | 30.76 | 45.76 | 60.76 | 75.76 | 90.76 | 105.76 | 3.0 |

| 1 diopter | 19.90 | 38.93 | 57.97 | 77.01 | 96.04 | 115.08 | 134.12 | 3.8 |

| 2 diopter | 24.35 | 47.80 | 71.24 | 94.68 | 118.13 | 141.57 | 165.02 | 4.7 |

| 3 diopter | 28.98 | 57.03 | 85.08 | 113.12 | 141.17 | 169.22 | 197.26 | 5.6 |

| 4 diopter | 33.72 | 66.48 | 99.24 | 132.00 | 164.77 | 197.53 | 230.29 | 6.6 |

| 5 diopter | 38.51 | 76.06 | 113.61 | 151.16 | 188.71 | 226.26 | 263.81 | 7.5 |

| 6 diopter | 43.35 | 85.74 | 128.12 | 170.50 | 212.89 | 255.27 | 297.65 | 8.5 |

Lasers with M² around 5.0 may include DPSS lasers and perhaps direct diode lasers using multiple lasers overlaid into a single beam. As with the rest of the information in this manual, these tables should be used as a starting point and not as the definitive final answer.

Laser beam with 1.0 milliradian full-angle divergence and M² of 5

(Spot size at the exit aperture of the projector = 3.30 mm)

| Distance in Meters | 5 | 10 | 15 | 20 | 25 | 30 | 35 | Divergence |

|---|---|---|---|---|---|---|---|---|

| No lens | 6.20 | 10.77 | 15.60 | 20.52 | 25.47 | 30.43 | 35.41 | 1.0 |

| 1 diopter | 20.79 | 38.38 | 55.98 | 73.58 | 91.18 | 108.78 | 126.39 | 3.6 |

| 2 diopter | 37.02 | 70.78 | 104.53 | 138.28 | 172.04 | 205.79 | 239.55 | 6.9 |

| 3 diopter | 53.42 | 103.56 | 153.69 | 203.83 | 253.96 | 304.10 | 354.23 | 10.1 |

| 4 diopter | 69.87 | 136.45 | 203.02 | 269.60 | 336.18 | 402.75 | 469.33 | 13.4 |

| 5 diopter | 86.34 | 169.38 | 252.42 | 335.47 | 418.51 | 501.55 | 584.59 | 16.7 |

| 6 diopter | 102.82 | 202.34 | 301.86 | 401.38 | 500.90 | 600.42 | 699.94 | 20.0 |

Laser beam with 2.0 milliradian full-angle divergence and M² of 5

(Spot size at the exit aperture of the projector = 1.72 mm)

| Distance in Meters | 5 | 10 | 15 | 20 | 25 | 30 | 35 | Divergence |

|---|---|---|---|---|---|---|---|---|

| No lens | 10.63 | 20.57 | 30.55 | 40.54 | 50.53 | 60.53 | 70.52 | 2.0 |

| 1 diopter | 16.33 | 31.27 | 46.23 | 61.19 | 76.16 | 91.12 | 106.09 | 3.0 |

| 2 diopter | 23.83 | 46.09 | 68.36 | 90.62 | 112.89 | 135.16 | 157.42 | 4.5 |

| 3 diopter | 31.89 | 62.15 | 92.41 | 122.67 | 152.92 | 183.18 | 213.44 | 6.0 |

| 4 diopter | 40.18 | 78.69 | 117.20 | 155.71 | 194.23 | 232.74 | 271.25 | 7.8 |

| 5 diopter | 48.58 | 95.56 | 142.36 | 189.25 | 236.14 | 283.03 | 329.92 | 9.5 |

| 6 diopter | 57.03 | 112.37 | 167.70 | 223.04 | 278.38 | 333.71 | 389.05 | 11.0 |

Laser beam with 3.0 milliradian full-angle divergence and M² of 5

(Spot size at the exit aperture of the projector = 1.33 mm)

| Distance in Meters | 5 | 10 | 15 | 20 | 25 | 30 | 35 | Divergence |

|---|---|---|---|---|---|---|---|---|

| No lens | 15.79 | 30.77 | 45.76 | 60.76 | 75.76 | 90.76 | 105.76 | 3.0 |

| 1 diopter | 20.58 | 40.11 | 59.64 | 79.18 | 98.71 | 118.25 | 137.78 | 3.9 |

| 2 diopter | 26.20 | 51.22 | 76.26 | 101.29 | 126.32 | 151.35 | 176.38 | 5.0 |

| 3 diopter | 32.20 | 63.18 | 94.17 | 125.15 | 156.13 | 187.11 | 218.09 | 6.2 |

| 4 diopter | 38.42 | 75.59 | 112.76 | 149.93 | 187.09 | 224.26 | 261.43 | 7.5 |

| 5 diopter | 44.77 | 88.25 | 131.74 | 175.23 | 218.72 | 262.21 | 305.70 | 8.7 |

| 6 diopter | 51.18 | 101.08 | 150.97 | 200.87 | 250.76 | 300.66 | 350.55 | 10.0 |

Normally, the SafetyScan lens is mounted outside of a laser projector, directly in front of the exit aperture, as securely as possible. However, the lens may also be mounted inside the projector for greater security. When mounted outside, ideally a lens mount should be used which provides three degrees of adjustment. Pangolin sells, and has produced engineering drawings of such a mount that provides all three degrees of adjustment. The mount designed by Pangolin is described in the next chapter. Each degree of adjustment is described below:

The first degree of adjustment is obvious – up/down. You adjust the lens upward and downward until the beam is diverged primarily in the audience area, but where the beam is not diverged above the heads of the audience members.

The second degree of adjustment is left-right. You will notice that that, in addition to affecting the beam divergence, the lens will also effectively steer the beam leftward or rightward if the center of the lens is not placed precisely over the center of the X-Y scanners. For best results, project a test pattern that has a vertical center line, such as the Pangolin Orientation test pattern. Move the lens leftward and rightward so that the center line of the test pattern is not affected (remains vertical and centered throughout the projected image).

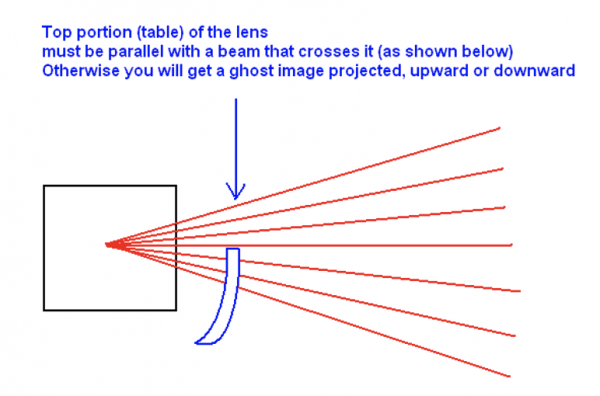

The third degree of adjustment is tilting the lens about the split at the top. If the top portion of the lens is at an angle with respect to the light coming from the X-Y scanners, there will be a kind of “ghost image”, which is a reflection off of the top surface of the lens. The lens angle should be adjusted so that the beams for the center of the projection are directly in angular alignment with respect to the top surface of the lens. Doing so will prevent the “ghost image” and the result will be perfect. The crude picture below shows the concept.

As mentioned above, we produced a video which explains all three degrees of lens adjustment (starting around time 11:20) here: http://www.youtube.com/watch?v=ooZ1C5gL7FA

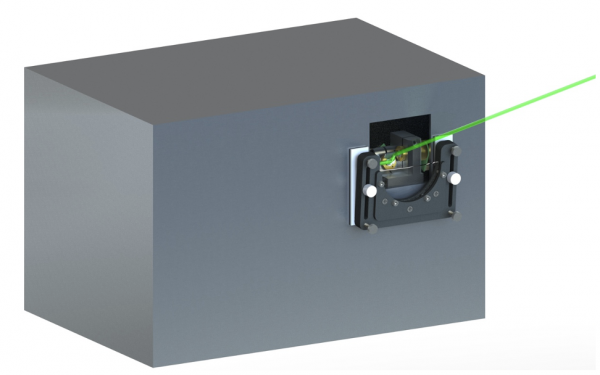

Kvant manufactures a lens mount that can be used to attach a SafetyScan lens to their laser projectors. A rendering of an example projector that uses a lens mount and SafetyScan lens is shown below.

To use the SafetyScan Lens and lens mount, do the following:

Once you have attached the lens mount to the laser projector, IT IS MANDATORY THAT YOU EVALUATE THE RELIABILITY AND SECURITY OF THIS ATTACHMENT, AND ENSURE THAT THE SAFETYSCAN LENS AND LENS MOUNT WILL NOT BECOME DISLODGED OR DISPLACED OVER TIME.

Due to our policy of continuous product improvement, information in this manual is subject to change without notice.

Intellectual Property Notice

SafetyScan is a trademark of Pangolin Laser Systems, Inc. All rights reserved.

SafetyScan lenses that are used in combination with certain projector configurations may be covered by U.S. Patent No. 8,506,087 and/or U.S. Patent No. 8,681,828.

The manufacture, use, offer for sale, or sale of laser projectors for audience scanning that incorporate SafetyScan lenses purchased from Pangolin or through a Pangolin-authorized sales channel are licensed under U.S. Patent No. 8,506,087 and U.S. Patent No. 8,681,828. No license is granted under these patents for lenses obtained from other sources.

THIS IS A LEGAL AGREEMENT (the “Agreement”) between you and Pangolin Laser Systems, Inc. (“Pangolin”) as licensor of the SafetyScan Lens and related materials you are receiving such as written manuals and tutorial videos (“Related Materials”). This Agreement provides you with the authorization to use the SafetyScan Lens and Related Materials subject to the terms and conditions herein. If you do not agree to all the terms and conditions of this Agreement, do not use the SafetyScan Lens and Related Materials. If you proceed to use the SafetyScan Lens or Related Materials, you thereby signify that you have agreed to all of the terms and conditions set forth below.

1. TERMS AND SCOPE: Your access to the SafetyScan Lens and Related Materials, whether through purchase or this manual downloaded from a web site, comes with certain restrictions. Specifically, Pangolin grants you only a limited, non-exclusive right to use the SafetyScan Lens and Related Materials in accordance with the terms and conditions of this Agreement.

2. ONE YEAR WARRANTY: Pangolin warrants the SafetyScan Lens and lens mount will perform substantially as described in this manual, under normal use for a period of one (1) year from the date of purchase.

3. LASER SAFETY NOTICE: It is possible for the SafetyScan Lens to become detached from the laser projector, or for its alignment to become affected during operation. Likewise it is possible for the laser power to suddenly increase beyond originally-tested levels. It is also possible that the SafetyScan lens chosen by the operator is not sufficient to ensure audience safety given a particular set of projection and audience parameters. These events and others may increase the risk of unsafe laser exposure. YOU ARE, THEREFORE, COMPLETELY AND SOLELY RESPONSIBLE FOR SCAN-FAIL SAFEGUARDS, BEAM STOPS, AUDIENCE SEPARATION DISTANCES, AIRCRAFT OBSERVERS, MEASUREMENTS AND CALCULATIONS, AND/OR ANY OTHER MEASURES NECESSARY TO PREVENT THE OVERALL LASER PROJECTION SYSTEM FROM PRESENTING A LASER SAFETY HAZARD.

4. LIMITATION OF LIABILITY: PANGOLIN SHALL NOT BE RESPONSIBLE FOR DAMAGES FOR LOSS OF USE OR OTHER DIRECT, INDIRECT, INCIDENTAL, CONSEQUENTIAL OR OTHER COSTS, EXPENSES, OR DAMAGES, INCLUDING LASER SAFETY RELATED DAMAGES, RESULTING FROM USE OF THE SAFETYSCAN LENS IN A MANOR THAT IS NOT IN STRICT ACCORDANCE WITH PANGOLIN’S INSTRUCTIONS, even if Pangolin has been advised of the possibility of such damages. You (and not Pangolin) assume the entire cost of all necessary servicing, repairs, safety measures or corrections. In no event shall Pangolin's total liability to you for all damages, losses, and causes of action (whether in contract, tort (including negligence) or otherwise) exceed the amount paid by you for the SafetyScan Lens and mount.

5a. LEGAL RIGHTS: Some states, provinces or other jurisdictions do not allow the limitation or exclusion of liability for incidental or consequential damages so the above limitations or exclusions may not apply to you. This warranty gives you specific legal rights, and you may also have other rights that vary from state to state, or by province or other jurisdiction.

5b. INDEMNIFICATION: You agree, at your own expense, to defend, indemnify and hold harmless Pangolin (including its officers, directors, employees and agents) from and against any third-party liabilities, claims, demands or suits asserting a claim or claims against Pangolin as a result of injury caused by your use of the SafetyScan Lens or any claim relating to your use of the SafetyScan Lens or Related Materials in a manner not in strict accordance with Pangolin’s instructions or documentation including this Agreement, and you agree to pay all damages awarded or agreed to under a settlement of such claim (provided, however, you may not enter into any settlement that imposes a financial obligation or admission of liability on Pangolin without Pangolin’s prior written consent).

6. AGREEMENT LENGTH AND TERMINATION PROCEDURE: This Agreement is effective until terminated. You may terminate this Agreement at any time by sending written notice to Pangolin Laser Systems, Inc. If you fail to comply with any provisions of this Agreement, the Agreement will terminate immediately without notice from Pangolin. Upon termination, whether by you (voluntarily) or by Pangolin (due to Agreement violations), you must A) stop using the SafetyScan Lens, mount, and Related Materials, and B) send a certified or traceable (e.g., FedEx) letter to Pangolin signed by you attesting to your compliance with this termination provision.

7. GOVERNING LAW AND SEVERABILITY: This Agreement shall be governed and construed in accordance with the laws of the United States and the State of Florida, without regard to any jurisdiction’s conflicts of law rules. If, for any reason, a court of competent jurisdiction finds any provision of this Agreement to be unenforceable, that provision of the Agreement shall be enforced to the maximum extent permissible so as to give effect to the intent of the parties, and the remainder of the Agreement shall continue in full force and effect. Venue and jurisdiction for any legal action shall be in the state or federal courts for Orange County, Florida.

8. ATTORNEYS’ FEES AND COSTS: In connection with any litigation, including appellate proceedings, arising out of or under this Agreement, Pangolin shall be entitled to recover reasonable out-of-pocket costs and reasonable attorneys’ fees.

9. INDEPENDENT CONTRACTORS: The parties to this Agreement are independent contractors, and this Agreement does not give rise to any partnership, joint venture, employment, franchise, or agency between the parties. Unless expressly authorized to do so under this Agreement, no party will have the power to bind any other party or incur obligations on any other party’s behalf without that party’s prior written consent.

10. THIRD-PARTY BENEFICIARIES: No provision of this Agreement is intended or shall be construed to provide or create any third-party beneficiary right or any other right of any kind in any person or entity, other than the parties and their successors and assigns.

11. WAIVER: No failure of a party to exercise or enforce any of its rights under this Agreement will act as a waiver of such rights.

12. NOTICES: Any notice to be provided under this Agreement shall be provided in writing and delivered by personal service (which shall include delivery by delivery service and overnight delivery service), sent via e-mail (but only if receipt of the email is confirmed by the receiving part), or mailed by United States certified mail as follows:

For Pangolin:

Pangolin Laser Systems, Inc

1265 Upsala Road, Suite 1165

Sanford, FL 32771 USA

For you: at the shipping address provided for shipment of the SafetyScan Lens provided in conjunction with this Agreement.

Such communications shall be effective on receipt when personally delivered or confirmed via email, and effective three (3) business days following deposit with the mail carrier for all other allowable forms of notice.

13. ENTIRE AGREEMENT: This Agreement constitutes the entire agreement with respect to the use of the SafetyScan Lens and mount, and supersedes all prior or contemporaneous understandings or agreements, written or oral, regarding such subject matter. NO REPRESENTATIVE, EMPLOYEE OR DEALER SHALL CREATE A WARRANTY OR IN ANY WAY INCREASE THE SCOPE OF THE WARRANTIES PROVIDED HEREIN. No amendment to or modification of this Agreement shall be binding unless in writing and signed by Pangolin Laser Systems, Inc.